What are the Benefits of Using Through Conduit Knife Gate Valves?

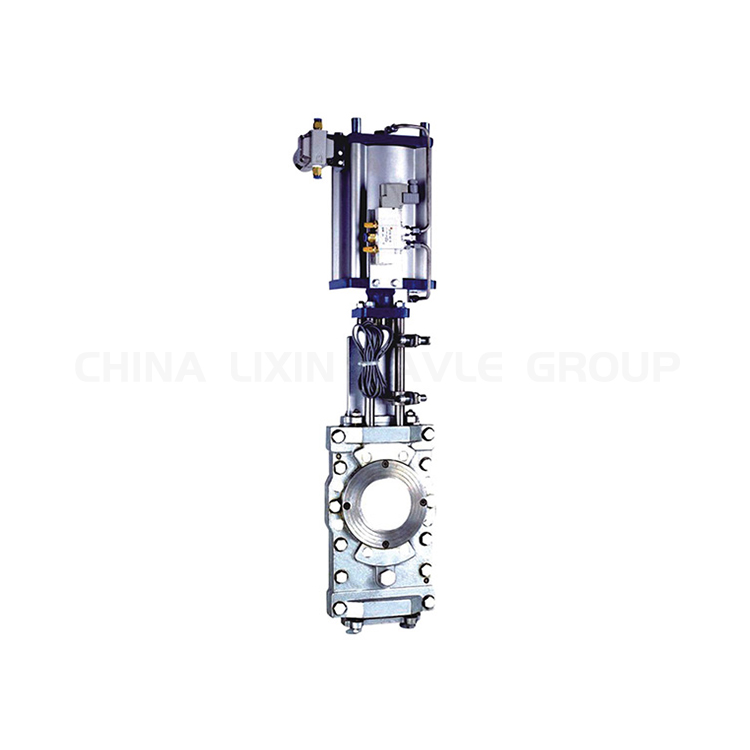

Knife gate valves are a type of industrial valve used to control the flow of fluids, typically liquids or slurries. They are characterized by a sharp, blade-like gate that slides across the flow path to open or close the valve. Knife gate valves are often used in applications where a tight seal is required, or where the flow contains solids or other particulates that could damage a conventional gate valve.

Through conduit knife gate valves are a specific type of knife gate valve that features a continuous flow path through the valve body. This design eliminates any restrictions in the flow path, resulting in several benefits over traditional knife gate valves.

Benefits of Through Conduit Knife Gate Valves

Reduced Pressure Drop: The continuous flow path eliminates any restrictions in the flow path, resulting in a reduced pressure drop across the valve. This can provide significant energy savings, especially in high-flow applications.

Increased Flow Capacity: The unrestricted flow path of through conduit knife gate valves allows for increased flow capacity compared to traditional knife gate valves. This makes them ideal for applications where large volumes of fluid need to be controlled.

Lower Maintenance Requirements: The simple design of through conduit knife gate valves results in lower maintenance requirements compared to traditional knife gate valves. The absence of pockets or crevices in the flow path helps prevent the accumulation of solids and other debris, which can lead to blockages and other issues.

Improved Durability: Through conduit knife gate valves are typically more durable than traditional knife gate valves due to their simplified design and the absence of potential failure points. This makes them ideal for applications in harsh or corrosive environments.

Versatility: Through conduit knife gate valves are available in a wide range of materials, sizes, and configurations, making them suitable for a variety of applications. They can be used in both on-off and throttling applications, and can handle a wide range of fluids, including liquids, slurries, and gases.

Applications of Through Conduit Knife Gate Valves

Through conduit knife gate valves are used in a wide range of applications, including:

Water and Wastewater Treatment: Through conduit knife gate valves are used to control the flow of water and wastewater in treatment plants. They are particularly well-suited for applications where the flow contains solids or other particulates, such as in sludge or slurry lines.

Mining and Mineral Processing: Through conduit knife gate valves are used in mining and mineral processing operations to control the flow of slurries and other abrasive materials. They are also used in tailing ponds and other applications where solids need to be retained.

Chemical and Petrochemical Processing: Through conduit knife gate valves are used in chemical and petrochemical processing plants to control the flow of corrosive fluids, such as acids and alkalis. They are also used in pipelines to transport chemicals and other hazardous materials.

Power Generation: Through conduit knife gate valves are used in power generation plants to control the flow of water, steam, and other fluids. They are also used in flue gas desulfurization (FGD) systems to remove sulfur dioxide from emissions.

Food and Beverage Processing: Through conduit knife gate valves are used in food and beverage processing plants to control the flow of liquids and slurries. They are particularly well-suited for applications where sanitation is critical, as they can be easily cleaned and sterilized.

Through conduit knife gate valves offer several benefits over traditional knife gate valves, including reduced pressure drop, increased flow capacity, lower maintenance requirements, improved durability, and versatility. These benefits make them ideal for a wide range of applications in various industries.