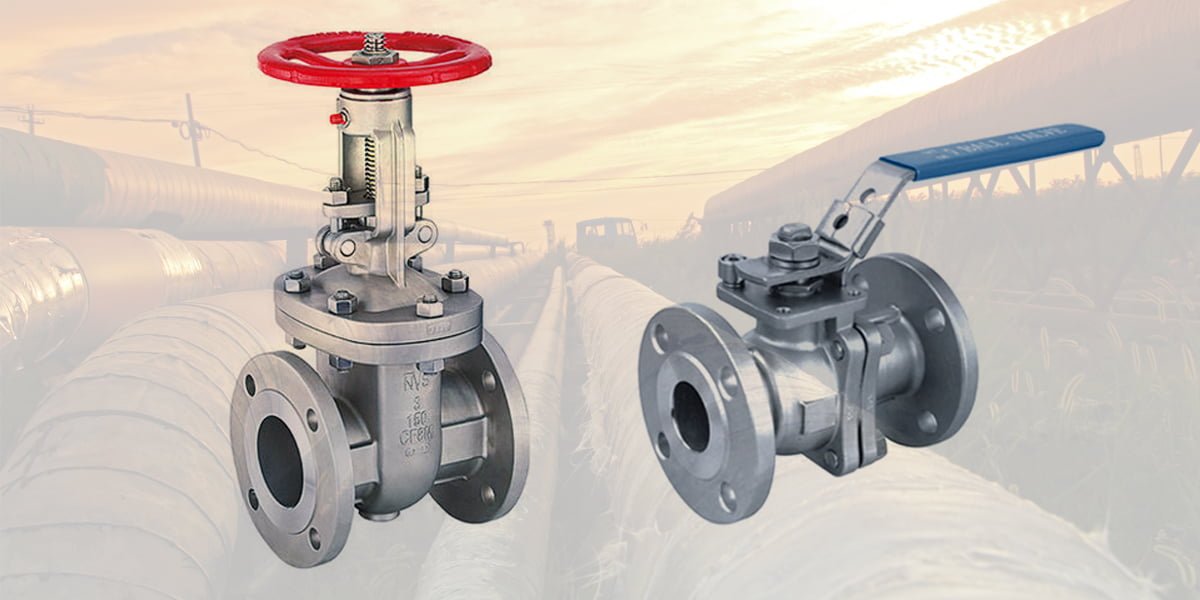

Gate Valve vs Ball Valve: Which is Best for Your Application?

Valves are essential components in piping systems, controlling the flow of fluids and gases. Two of the most common types of valves are gate valves and ball valves. Each type has its own unique advantages and disadvantages, making it important to understand their differences when selecting the best valve for a specific application.

Gate Valve

A gate valve is a linear motion valve that uses a wedge-shaped gate to obstruct or allow flow. When the valve is open, the gate is lifted out of the flow path, creating a straight-through opening. When the valve is closed, the gate is lowered into the flow path, completely blocking the flow.

Advantages of Gate Valves:

- Precise flow control: Gate valves offer good flow regulation, as the gate can be partially opened or closed to modulate the flow rate.

- Straight-through flow: The gate creates a straight-through flow path when fully open, minimizing pressure drop.

- Pressure-tolerant: Gate valves are suitable for high-pressure applications.

- Long service life: Gate valves have a long service life, especially when properly maintained.

Disadvantages of Gate Valves:

- Wide body: The gate inside the valve requires more space, resulting in a wider valve body.

- Manual operation: Gate valves are typically operated manually with a handwheel or actuator, which can be slow and labor-intensive.

- Not suitable for quick isolation: Gate valves are not suitable for applications where quick isolation is required, as they require multiple turns to open or close.

Ball Valve

A ball valve is a rotary motion valve that uses a spherical ball to control the flow of fluid. When the valve is open, the ball is rotated 90 degrees, aligning the hole in the ball with the flow path. When the valve is closed, the ball is rotated 90 degrees in the opposite direction, blocking the flow path.

Advantages of Ball Valves:

- Quick isolation: Ball valves can be quickly closed or opened by rotating the ball 90 degrees, making them ideal for applications where rapid flow control is required.

- Bi-directional flow: Ball valves allow flow in both directions.

- Compact design: Ball valves are more compact than gate valves, requiring less space.

- Low pressure drop: The ball creates minimal flow resistance, resulting in low pressure drop.

- Automated actuation: Ball valves can be easily automated with electric, pneumatic, or hydraulic actuators.

Disadvantages of Ball Valves:

- Fair flow control: Ball valves do not offer the same level of flow control as gate valves, as the ball can only be fully open or fully closed.

- Limited pressure tolerance: Ball valves are not as pressure-tolerant as gate valves, especially in larger sizes.

- Shorter service life: Ball valves typically have a shorter service life than gate valves, especially in abrasive or corrosive applications.

Comparison of Gate Valves and Ball Valves

The following table provides a summary of the key differences between gate valves and ball valves:

| Feature | Gate Valve | Ball Valve |

|---|---|---|

| Flow Control | Good | Fair |

| Pressure Drop | Low | Very low |

| Compactness | Bulky | Compact |

| Quick Isolation | No | Yes |

| Corrosion Resistance | Moderate | Good |

| Service Life | Long | Moderate |

| Cost | Moderate | Low |

Best Application for Each Type

Gate valves are best suited for applications where precise flow control, high pressure tolerance, and long service life are required. Some common applications include:

- Water and wastewater treatment plants

- Power plants

- Refineries

- Chemical processing plants

Ball valves are best suited for applications where quick isolation, compact design, and low pressure drop are required. Some common applications include:

- Gas pipelines

- HVAC systems

- Irrigation systems

- Food and beverage processing plants

Additional Considerations

When selecting a gate valve or ball valve for a specific application, it is important to consider the following factors:

- Pressure rating: Ensure the valve is rated for the maximum operating pressure.

- Temperature range: Consider the temperature range of the fluid being handled.

- Material of construction: Select a valve material compatible with the fluid and operating environment.

- Maintenance: Consider the maintenance requirements and accessibility of the valve.

- Actuator type: Determine if manual or automated operation is required.

By carefully considering the factors discussed in this article, you can select the best gate valve or ball valve for your specific application.