Rubber Lined Gate Valves vs. Butterfly Valves: Which is Right for You?

Choosing the right valve for your industrial application can be a critical decision impacting efficiency, cost, and safety. Two popular choices are rubber lined gate valves and butterfly valves. Both offer unique advantages and disadvantages, making the selection process dependent on your specific needs.

Here’s a breakdown of their key features to help you decide:

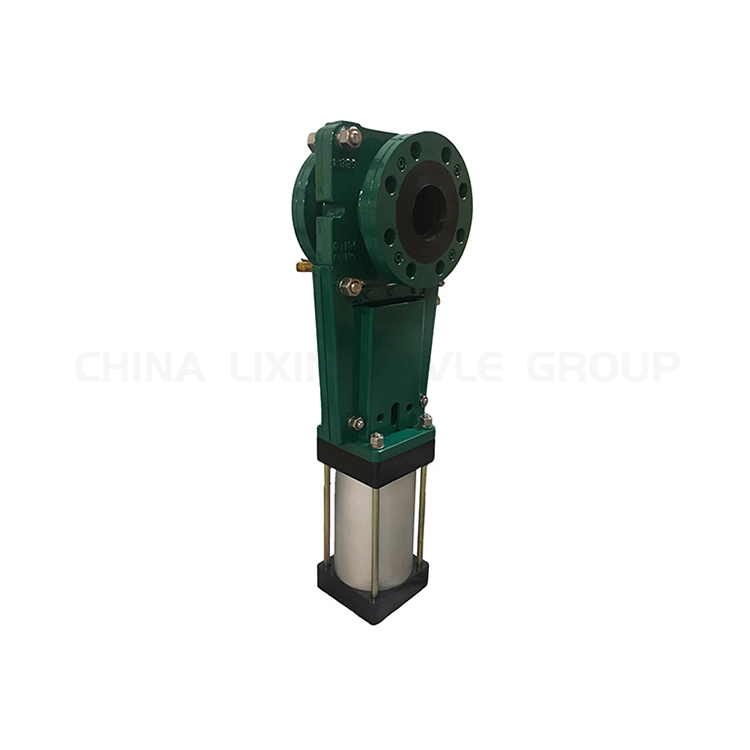

Rubber Lined Gate Valves

Key features:

Full bore design: Provides minimal flow restriction and pressure drop.

Excellent shut-off: The rubber lining ensures a tight seal, ideal for leak-proof applications.

Abrasion and corrosion resistance: The rubber lining protects the valve body from abrasive and corrosive media.

Suitable for slurries and solids: Can handle fluids with suspended particles without clogging.

Lower maintenance: Requires less frequent maintenance compared to butterfly valves.

Disadvantages:

Larger and heavier: Requires more space and support structures.

Higher cost: Initial investment can be higher than butterfly valves.

Slower operation: Opening and closing mechanisms are slower.

Butterfly Valves

Key features:

Compact and lightweight: Requires less space and is easier to install.

Lower cost: Generally more affordable than rubber lined gate valves.

Fast operation: Quarter-turn mechanism allows for quick opening and closing.

Good for throttling flow: Can be used to regulate flow by adjusting the disc position.

Disadvantages:

Reduced flow capacity: The disc creates a flow restriction, leading to higher pressure drops.

Less effective sealing: May not be suitable for applications requiring tight shut-off.

Limited abrasion resistance: The exposed disc can be susceptible to wear from abrasive media.

Higher maintenance: May require more frequent maintenance due to wear on the disc and seat.

Choosing the Right Valve

The best choice for your application depends on several factors, including:

Media characteristics: Consider the fluid type, presence of solids, and potential for corrosion or abrasion.

Flow requirements: Analyze the desired flow rate and allowable pressure drop.

Space constraints: Consider the available space for valve installation.

Budget: Evaluate the initial cost and long-term maintenance expenses.

In general

Rubber lined gate valves are ideal for applications requiring tight shut-off, handling abrasive or corrosive media, and where flow restriction is a concern.

Butterfly valves are suitable for applications where space is limited, cost is a major factor, and fast operation is needed. They are also suitable for throttling flow.

Remember: Consult with a valve manufacturer to discuss your specific needs and ensure you select the optimal valve for your application.