As a market leader, we stand out with our rich

Wafer Butterfly Valve Factory categories, wide range of

Horizontal Check Valve Factory choices, and our ability to respond quickly to customer needs. Our

Modulating Ball Float Valve is favored by consumers for its excellent performance and reasonable price. We are always committed to improving production processes and technology, and constantly optimizing production, operation and management levels. Guided by market development trends and customer needs as the core, we continue to break through technological and process bottlenecks and achieve rapid expansion of production capacity and rapid development of the enterprise. We insist on innovation in products, technology and management to ensure that we provide customers with the best service, the most valuable products and the fastest delivery.

Related Blogs

Butterfly valves are a type of valve that uses a rotating disk to control the flow of fluid. They are commonly used in HVAC, plumbing, and industrial applications. Butterfly valves are relatively easy to install, but there are a few steps that you should follow to ensure a proper installation. Materials Butterfly valve Flanges or unions Gaskets Bolts and nuts Wrench Pipe sealant Step 1: Prepare the valve and flanges Before you begin the installation, you need to prepare the valve and flanges. This includes cleaning the surfaces of the valve and flanges, and applying a thin layer of pipe sealant to the gaskets. Step 2: Assemble the valve and flanges Once the valve and flanges are prepared, you can begin to assemble them. Place the valve between the flanges, and align the bolt holes. Insert the bolts and nuts, and tighten them until the valve is securely in place. Step 3: Connect the piping Once the valve is assembled, you can connect the piping. Be sure to use the correct size and type of pipe for the application. Step 4: Test the valve Once the piping is connected, you can test the valve to make sure it is working properly. Open the valve and close it several times to check for leaks. […]

Construction Butterfly valves are typically constructed with a cast iron or stainless steel body and a rubber or plastic disc. The disc is attached to a shaft that is supported by bearings at each end. The shaft is turned by a handle or actuator, which can be manual or automated. Advantages Butterfly valves offer a number of advantages over other types of valves, including: Compact size: Butterfly valves are relatively small and lightweight, making them easy to install and maintain. Low pressure drop: The streamlined design of the butterfly valve results in a low pressure drop, which can save energy costs. Quick operation: Butterfly valves can be opened or closed quickly, making them […]

FAQ

What Valve Products Do You Offer?

How Is The Quality of Your Products?

We strictly test each product, using the most advanced testing equipment and strict scientific management. From design to production, we strictly follow the ISO production management system to ensure product quality meets factory standards.

How Is Your Customer Service?

We value customer satisfaction and provide professional pre-sales and after-sales services. If you have any questions or need support, please feel free to contact our customer service team.

What Is Your R&D Capability?

We have a strong R&D team dedicated to technological innovation and product improvement. We continuously introduce new products to meet the changing needs of our customers.

Do You Provide Customized Services?

Yes, we can customize products according to customers’ specific needs. If you have special requirements, you can contact our sales team for customized solutions.

Do You Have International Certifications?

Yes, our products have passed multiple international certifications, such as ISO 9001, CE, API 6D, etc.

Why Choose Lixin?

Excellent Quality Management

Lixin maintains rigorous quality management systems to ensure that each product meets international standards. With specialized testing equipment and an annual production capacity of 20,000 tons, their commitment to quality is unwavering.

Comprehensive Quality Assurance

Lixin rigorously tests every product, adhering to ISO production management systems to ensure that product quality consistently meets factory standards.

Advanced Global Fluid Control Solutions

Lixin focuses on designing and producing valves and related products, striving to provide cutting-edge fluid control solutions worldwide. Customization options are also available to create additional value for customers.

Robust Technical Support

With over 450 employees, including more than 50 senior and intermediate engineering technicians, Lixin boasts a strong technical team. Their 50,000-square-meter facility houses CNC machining centers, various large and medium-sized equipment, and specialized testing devices.

Diverse Product Line

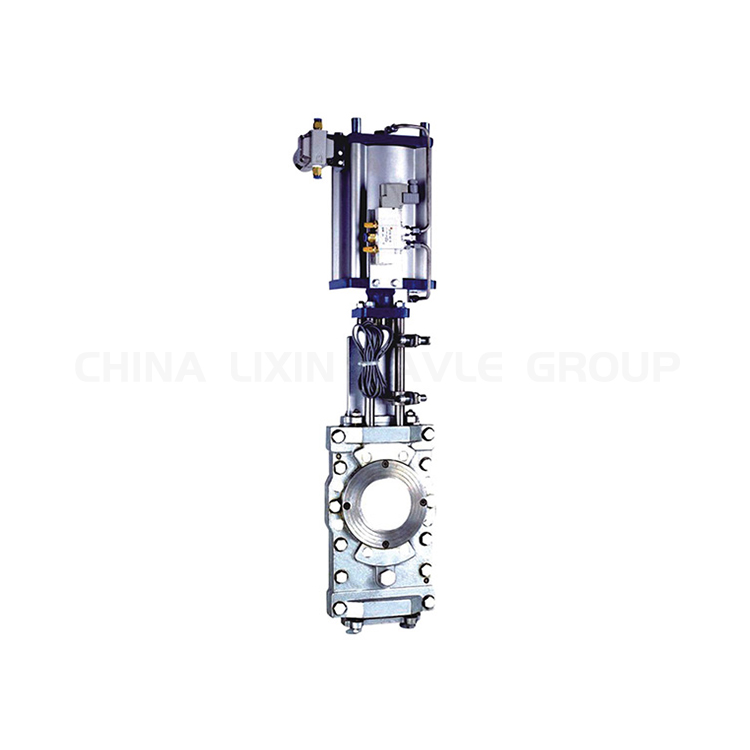

Lixin manufactures a wide range of valves, including knife gate valves, plug valves, butterfly valves, ball valves, and ceramic valves.

Global Market Expansion

Lixin actively welcomes collaboration to create a brilliant future, aiming to expand the global valve market, promote the Lixin brand, and revitalize domestic industrial development.

Lixin Valve Group Co., Ltd. is a national-level non-regional group focusing on the research and development, production, sales and service of valves. Since its establishment in 2000, Lixin has continuously innovated technology and grown in scale. We are committed to providing customers with global advanced fluid control solutions and customizing products according to your needs to create more value for customers. If you need high-quality knife gate valves, Lixin Valve Group is your first choice!