A Complete Guide To Butterfly Valve

Butterfly valves are versatile components widely used in various industries for controlling flow. From their different types to installation procedures and applications, this comprehensive guide covers all aspects of butterfly valves.

What Is A Butterfly Valve?

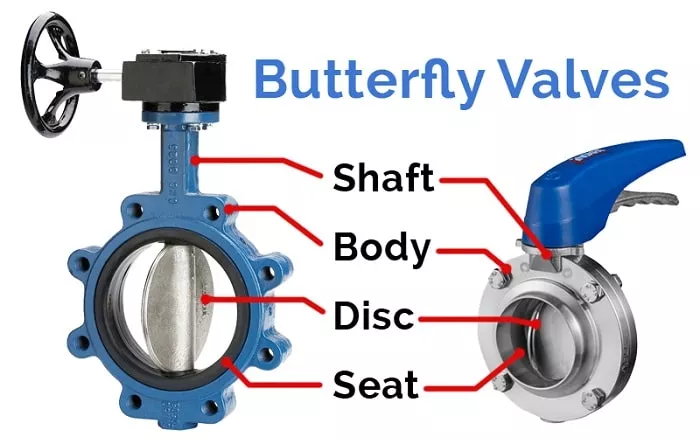

Butterfly valve is a simple quarter-turn rotary valve. Its disc-shaped flap is mounted on the central axis of the pipeline and rotates through 90 degrees to open, close or regulate the fluid. Butterfly valves are widely used in various industrial fields, and are favored for their compact structure and easy operation.

Butterfly Valve Symbol

The symbol for a butterfly valve is usually represented by a circle with a crosshair through the center of the circle, representing the position of the valve shaft. The curve perpendicular to the valve shaft represents the butterfly plate.

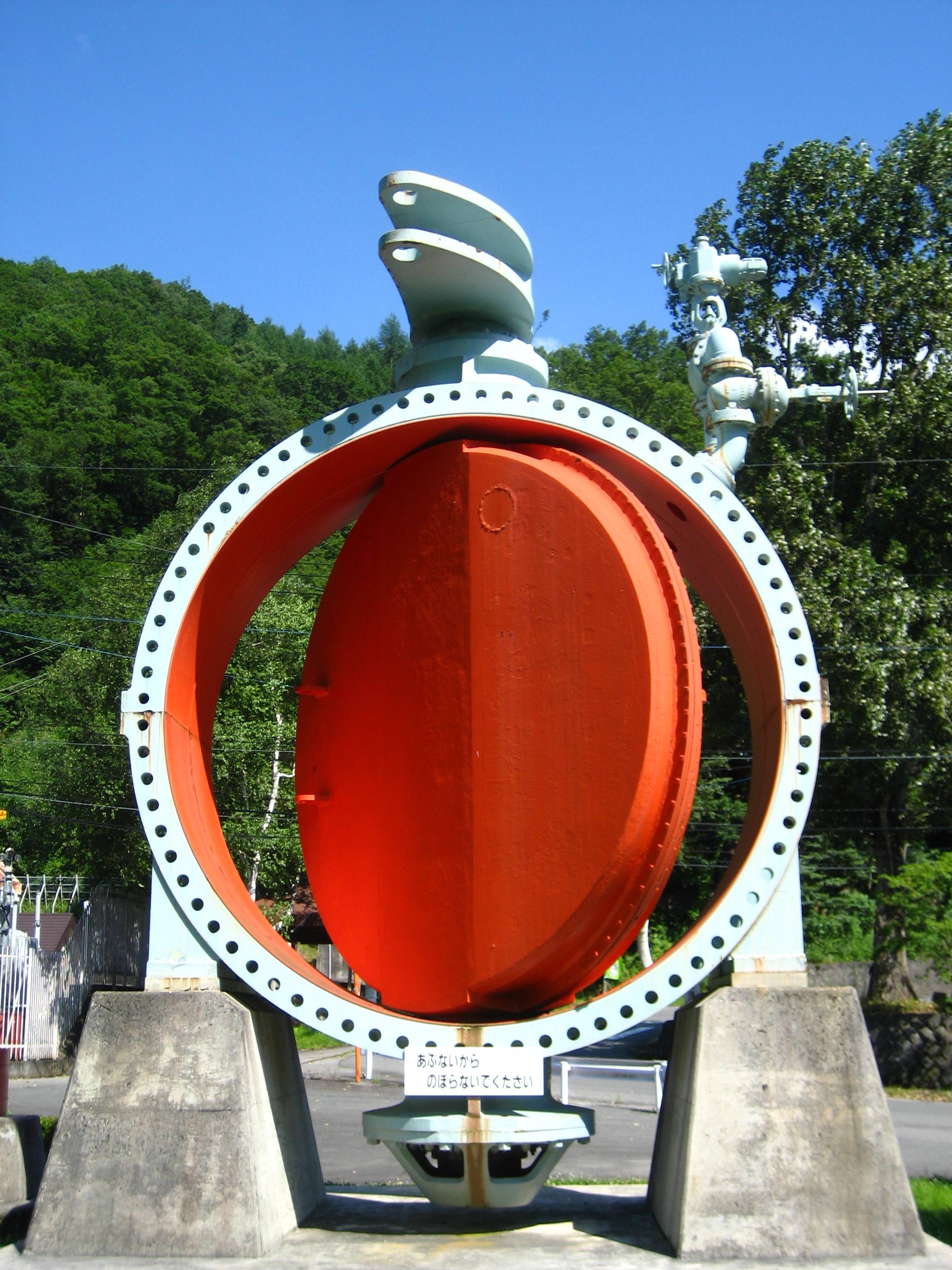

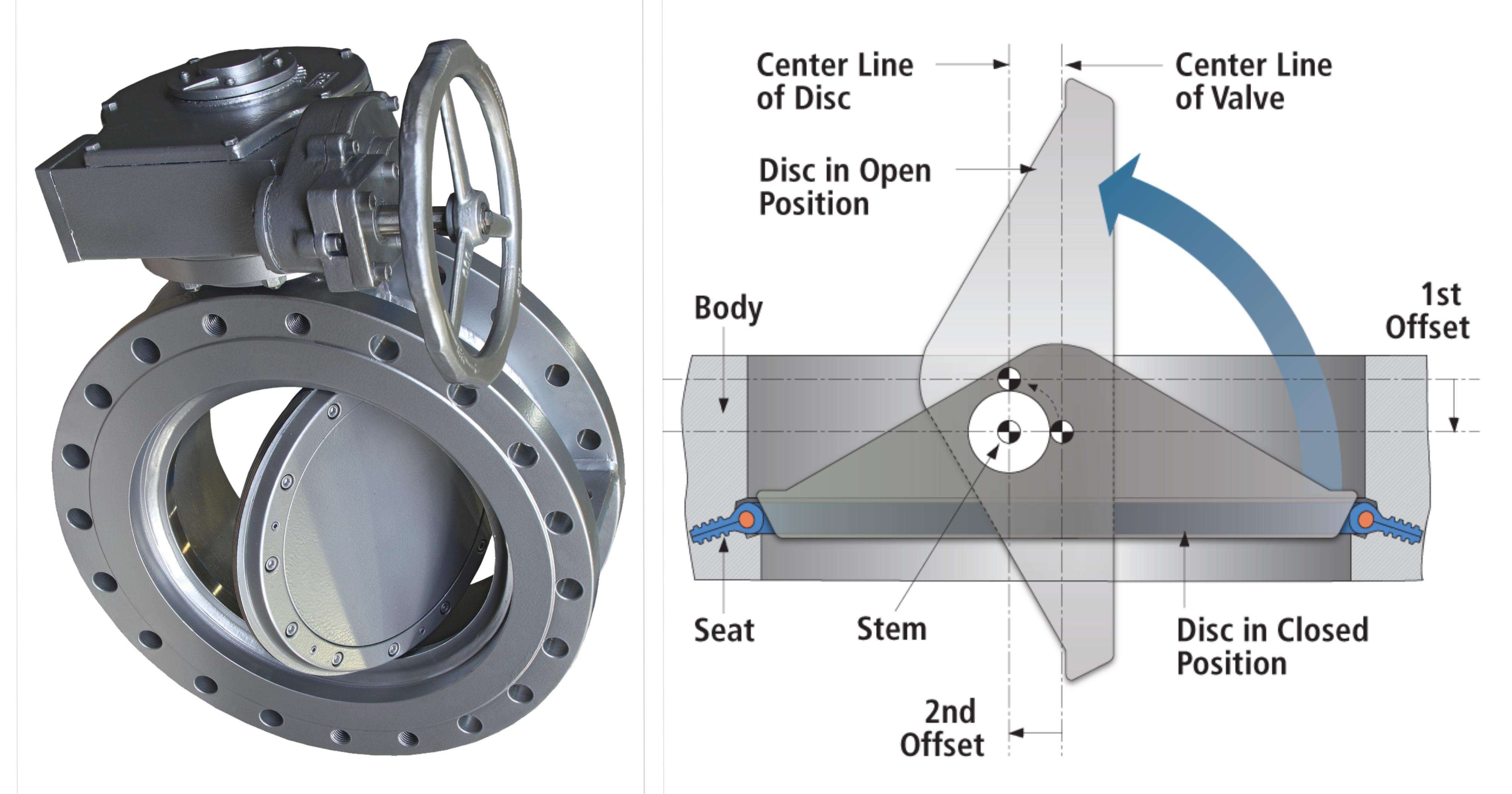

What Is Triple Offset Butterfly Valve?

Triple Offset Butterfly Valves have a unique construction characterized by three separate eccentrics. These eccentrics include shaft eccentricity, seat taper angle and flap seal taper angle. This ingenious design minimizes friction and wear while enhancing sealing capability. As a result, the Triple Eccentric Butterfly Valve is ideally suited for high pressure and high temperature applications where reliable performance is required.

What Is Wafer Type Butterfly Valve?

Wafer Type Butterfly valves are compact and lightweight, and are sandwiched between two pipe flanges without the need for additional flanges. They are ideal for applications where space is limited and pressure is low.

What Is Lug Type Butterfly Valve?

Lug Type Butterfly Valves have threaded inserts or lugs on both sides of the valve body, allowing easy installation and removal from the pipeline without disturbing the adjacent pipes. They are commonly used in applications requiring frequent maintenance.

How Does A Butterfly Valve Work?

When the valve is closed, the disk rotates perpendicular to the fluid, completely blocking it. When open, the disc rotates parallel to the fluid, allowing fluid to pass through. Quarter-turn operation makes butterfly valves quick and easy to control.

Do Butterfly Valves Need Gaskets?

Yes, butterfly valves usually require gaskets to ensure a tight seal between the valve body and the pipe flange. The type of gasket used depends on the fluid being conveyed and the operating conditions.

What Are Butterfly Valves Used For?

Butterfly valves are used in a wide range of industries including water treatment, HVAC, oil and gas, chemical processing, and food and beverage. They are suitable for on/off and throttling applications, providing reliable flow control. High Performance Butterfly Valves

What Is The Function Of Butterfly Valve?

The main function of a butterfly valve is to regulate the flow of fluid in a pipeline by opening or closing the valve completely, or controlling the flow rate by adjusting the degree of opening.

How To Install A Butterfly Valve?

Installing a butterfly valve involves proper alignment with the pipeline, ensuring the valve operates smoothly and effectively. It’s essential to follow manufacturer guidelines and torque specifications for flange connections.

Gate Valve Vs Butterfly Valve (What Is The Difference)

Both gate and butterfly valves are used for flow control, but they differ in design and operation. Gate valves use a sliding gate to control flow, while butterfly valves use a rotating flap. Gate valves are better suited for on/off applications, while butterfly valves are better suited for throttling.

Top Butterfly Valve Manufacturers

Some of the top butterfly valve manufacturers include Xomox Corporation, Bray International, Emerson Electric Co., Crane Co., and Flowserve Corporation.

FAQs on Butterfly Valves

What are the advantages of Lixin butterfly valve?

High-quality materials: Lixin uses high-quality materials to manufacture butterfly valves, such as cast iron, ductile iron, stainless steel, etc. to ensure durability and reliability.

Advanced Manufacturing Process: Lixin adopts advanced manufacturing process and equipment to ensure the precision and quality of butterfly valves.

Strict Quality Control: Lixin conducts strict quality control tests on all butterfly valves to ensure that they meet international standards.

Rich experience: Lixin has many years of experience in butterfly valve manufacturing and can provide professional technical support and service for customers.

Competitive price: Lixin offers competitive price to provide customers with cost-effective products.

How to choose the right butterfly valve?

The following factors need to be considered when choosing the right butterfly valve:

Application: The application of the butterfly valve determines its material, pressure level and connection method.

Media type: Different media need to choose different materials, such as corrosive media need to choose fluorine lined butterfly valve.

Temperature and pressure: Temperature and pressure level determine the structure and material of butterfly valve.

Size and connection: According to the pipeline size and connection mode, choose the appropriate butterfly valve.

What after-sales service does Lixin provide?

Lixin provides comprehensive after-sales service, including:

Installation guidance: Lixin provides professional installation guidance to ensure the correct installation of butterfly valves.

Maintenance: Lixin provides maintenance service for butterfly valves to prolong their service life.

Technical support: Lixin provides professional technical support to answer customers’ questions.

Spare parts supply: Lixin provides spare parts supply for butterfly valves, which is convenient for customers to repair and replace.

If you have any questions about butterfly valves, please feel free to contact us.