Our

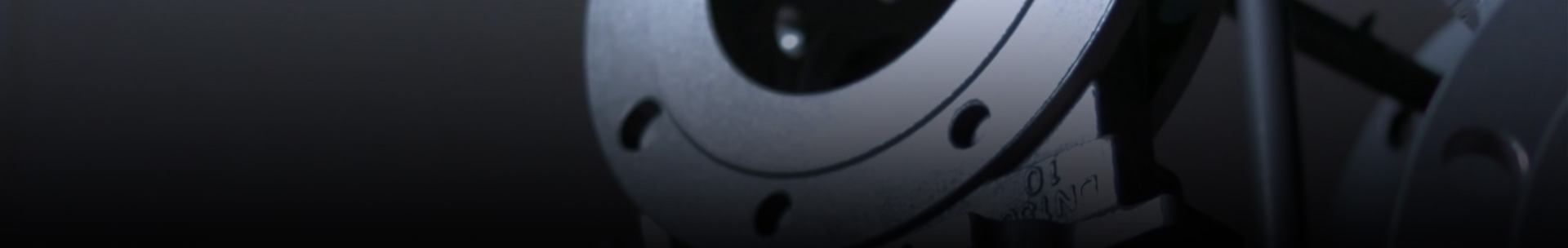

CI Gate Valve,

3 Way Ball Valve Manufacturer comply with national standards and industry guidelines and meet performance indicators. The company has innovated, strived for excellence, and built a complete product system and a unique product line. We remain steadfast and determined. It was difficult to start a business, but after several generations of hard work, we have become the modern enterprise we are today. We strive diligently to achieve the expected goals of product quality, economic benefits, and market competitiveness to meet market needs. Once a belief is established, there should be no hesitation, maintain a sense of competition, and implement it efficiently. Face challenges head-on, move forward with focus, and take the initiative.

Related Blogs

What Is a Slab Gate Valve? The slab gate valve is different from other knife gate valve. It is a full-bore closing member with a parallel gate. Its structure is designed to be full-bore. When it is opened, it will not hinder the liquid in the pipeline, thereby having no effect on the pressure drop […]

Whats Eccentric Hemispherical Valve? The eccentric hemispherical valve is a high-performance industrial valve designed for demanding applications. Its innovative design features an eccentric (off-center) hemispherical disc that provides superior control, sealing, and durability. This type of valve is particularly well-suited for handling fluids under high pressure and temperature conditions, making it a preferred choice in […]

Hi there! The article is about API 6D Plug Valves, which are essential components in pipeline systems for regulating fluid flow. You will benefit from understanding their construction, operation principles, and the variety of types available, such as lubricated and non-lubricated valves. Knowing this ensures informed decisions in selecting valves for specific industrial applications, ensuring […]

What Is A Check Valve on A Well Pump? A check valve on a well pump serves a crucial role in ensuring the efficiency and reliability of the entire water delivery system. Essentially, a check valve is a mechanical device designed to permit fluid flow in one direction only. In the context of well pumps, […]

In my extensive experience functioning with various casting materials, I have actually discovered that A216 WCB material, specified under the ASTM A216 criterion, is very related to for its unique combination of homes. A216 WCB is a carbon steel spreading grade that is mainly made use of in pressure-containing parts, and its prevalent application is […]

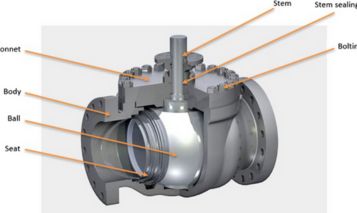

Introduction Definition of Big Size Ball Valve A big size ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of fluids through it. These valves are specifically designed for applications requiring large pipe diameters and high flow rates. Big size ball valves typically range […]

Have you ever wondered if a bad valve cover gasket can cause the Check Engine Light? This article dives into the importance of the valve cover gasket in preventing oil leaks and engine damage. By understanding the symptoms, causes, and diagnosis of a faulty gasket, you can benefit from early detection and prevention of serious engine […]

Reading this article on big size ball valves will provide valuable insights into the key features, materials, and applications of these essential components. As an expert in the field, I have highlighted the critical design elements, material options, and performance metrics that are crucial for selecting the right valve for various industries. By understanding these aspects, […]

What is PSI? PSI is a widely used unit of pressure measurement in the United States and other countries. It quantifies the force exerted over an area of one square inch. Unlike the Pascal (Pa), the SI unit of pressure that measures force in Newtons per square meter, PSI utilizes pounds-force per square inch. This […]

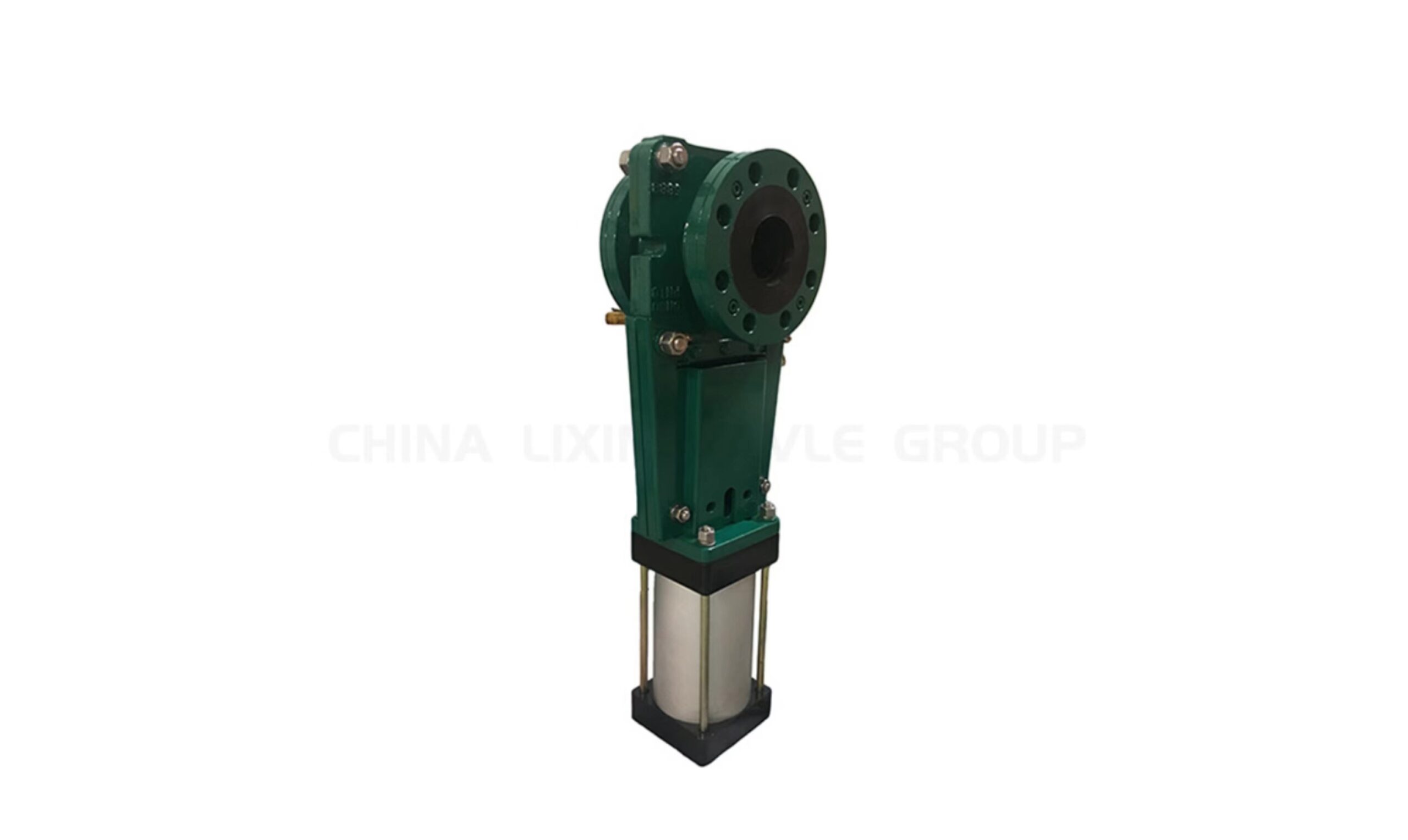

Valve Control Valve control is a key component in industrial automation, ensuring the safety, efficiency and stability of the production process. By accurately controlling the switching state and flow rate of valves, the fluid flow rate, pressure and temperature can be regulated, thus optimizing the process parameters and improving the production efficiency. Modern valve control […]

What is API 600? API 600 Standard API 600 is known as the “Steel Gate Valve Design and Manufacturing Specification.” This standard applies to steel gate valves used in petroleum, natural gas, and related industries, covering the following key aspects: Design Requirements: API 600 specifies the design criteria for steel gate valves, including structural strength, […]

What is API 6D Ball Valve? API 6D ball valves comply with American Petroleum Institute (API) standard 6D and are commonly used in oil and gas, chemical and other industrial fields. The ball valves offered by us fully comply with the design, manufacturing and testing standards of API 6D specifications. Ball valves are […]

Today, all industries are actively seeking solutions to reduce emissions and increase sustainability. In the field of industrial processes, the application of valves has become an important area of innovation. In particular, low emission valves, such as gate and ball valves, have become a key solution for minimizing disorganized emissions and improving environmental performance. In […]

What is a Gate Valve? Gate valves are a common type of valve used to control the flow of fluids. It has a simple structure and consists of a gate valve body, gate valve bonnet, gate valve stem and valve flap. The valve flap is usually a flat or circular door plate that […]

Butterfly valves are versatile components widely used in various industries for controlling flow. From their different types to installation procedures and applications, this comprehensive guide covers all aspects of butterfly valves. What Is A Butterfly Valve? Butterfly valve is a simple quarter-turn rotary valve. Its disc-shaped flap is mounted on the central axis of […]

In the intricate world of fluid systems, it is vital to ensure unidirectional flow. Check valves, often referred to as check valves, prevent any backward flow, thus ensuring that the fluid flows only in the desired direction. What is a Check Valve? Check valves act as reliable gatekeepers in fluid piping systems, allowing fluid […]

The valve stem is a crucial component between the valve handle and the valve gate, controlling the opening or closing of the valve. Over time, the valve stem may become loose, causing internal leaks and other issues. Tightening the valve stem is a relatively simple procedure but requires the proper technique and tools. This article […]

Identifying whether a valve is open or closed can be a perplexing task for both homeowners and professionals. While butterfly and ball valves offer clear visual cues through the orientation of their handles, gate valves and check valves lack such obvious indicators, making it difficult to discern their status. Often, one must rely on the […]

Valve actuators are crucial parts in many industries. They control how much fluid flows through valves. These devices move and adjust valves. This allows industrial processes to work well. We’ll look at different actuator types here: electric, pneumatic, hydraulic, and manual. We’ll go over their traits, advantages, how they work, and what they’re used […]

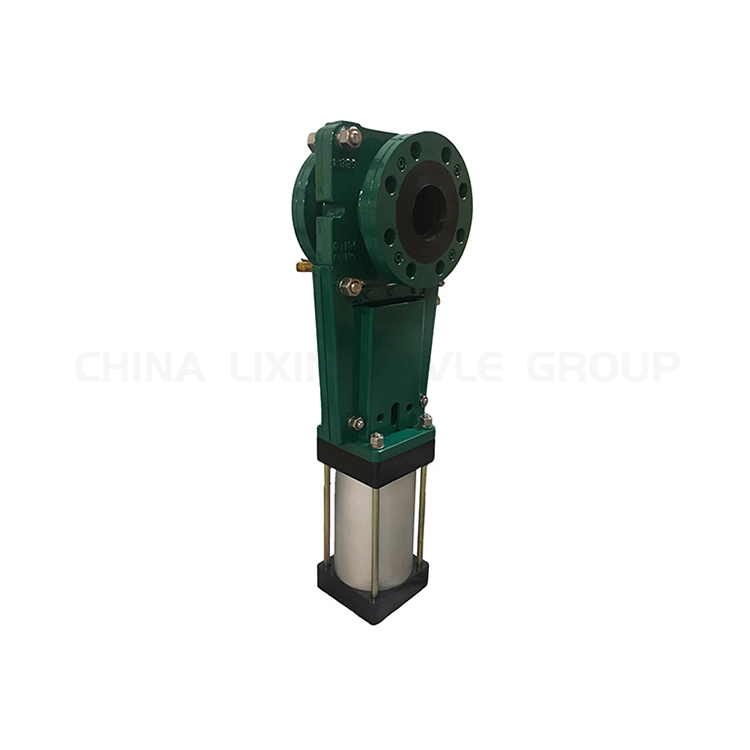

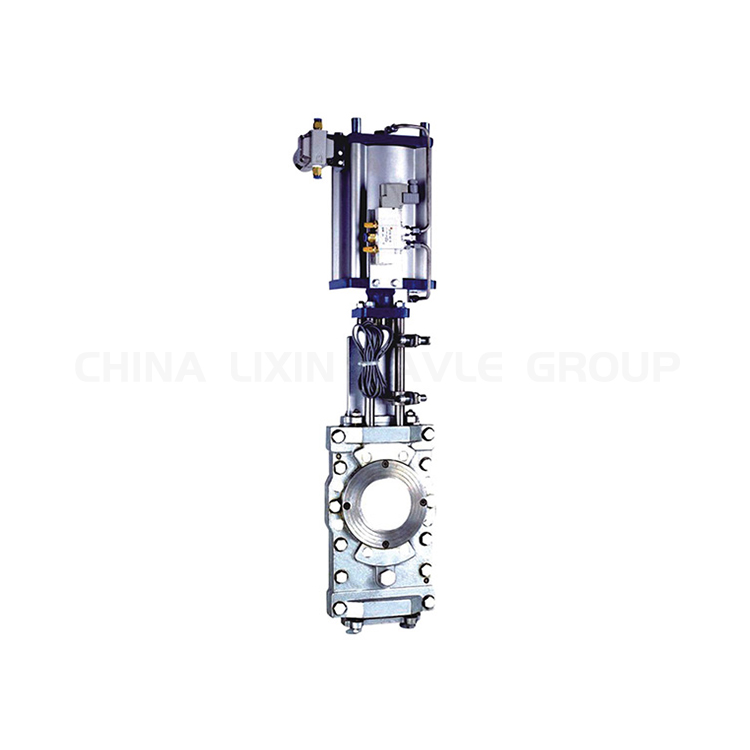

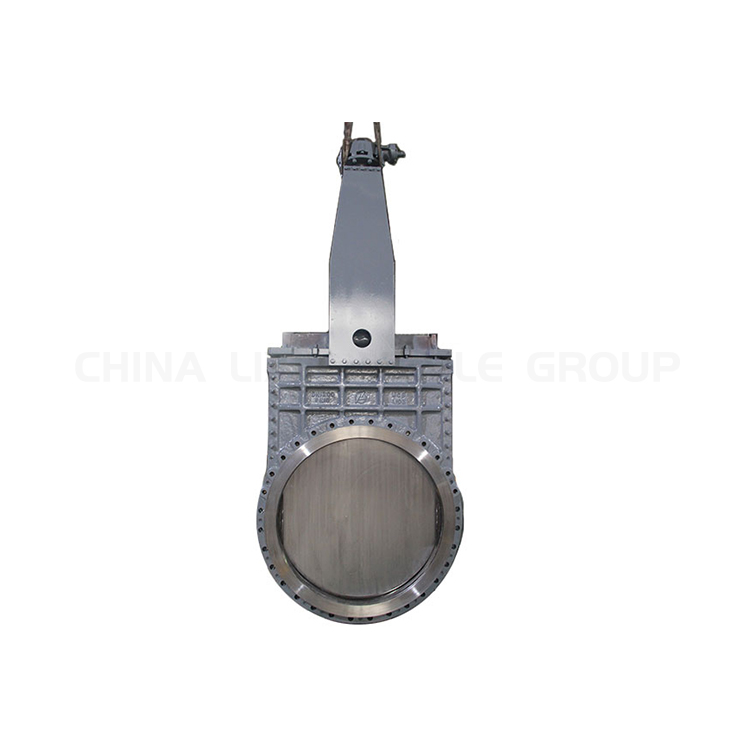

What is the function of a knife gate valve? A knife gate valve is a critical component in many industrial applications, providing a dependable and efficient method of controlling the flow of diverse fluids. As the name implies, this valve uses a sharp-edged gate to cut through the media and control its flow. A knife […]

Understanding the Purpose and Functionality of Knife Gate Valves The purpose of a knife gate valve is to let fluids pass through when opened yet to maintain a tight seal when closed. They are commonly employed in situations when handling caustic or abrasive compounds is involved. Depending on the needs of the system, knife gate […]

Introduction to Knife Gate Valves Knife gate valves are widely used in various industries because of their powerful functions. In this article, we describe from how they work to benefits, applications, types, selection factors, installation, maintenance, common issues and top manufacturers of knife gate valves. After reading this article, you will have a comprehensive understanding […]

Rubber lined gate valves are a popular choice for industrial applications due to their corrosion resistance, durability, and tight shut-off capabilities. However, their initial cost can be higher than other valve types. This blog post will explore various cost-saving strategies you can implement when choosing and using rubber lined gate valves. Choosing the […]

Choosing the right valve for your industrial application can be a critical decision impacting efficiency, cost, and safety. Two popular choices are rubber lined gate valves and butterfly valves. Both offer unique advantages and disadvantages, making the selection process dependent on your specific needs. Here’s a breakdown of their key features to help […]

Rubber lined gate valves are popular choices for various applications due to their excellent sealing capabilities and resistance to corrosion and abrasion. However, to ensure optimal performance and longevity, proper installation and maintenance are crucial. Installation Tips Inspection: Before installation, thoroughly inspect the valve for any damage or defects. This includes checking the rubber […]

When selecting a gate valve, one crucial decision is choosing between a rubber-lined and a metal-seated valve. Both types have their own advantages and disadvantages, and understanding these differences is critical for making the right choice for your specific needs. Rubber-lined gate valves These valves feature a rubber lining on the inside of the […]

Gate valves are essential components in many industrial and municipal systems, controlling the flow of liquids and gases. While various materials are used for gate valve construction, rubber-lined gate valves offer distinct advantages that make them a preferred choice in specific applications. Here are some key benefits of using rubber-lined gate valves 1. Excellent […]

Maintaining a ceramic knife gate valve is crucial to ensure its proper functioning and longevity. Here’s a general guide on how to maintain it: Regular Inspection Check the valve for any signs of wear or damage, especially focusing on the sealing surfaces and the gate itself. Look for cracks, corrosion, or any loose parts. Packing Adjustment […]

Introduction In industrial applications, selecting the right valve type is crucial for project success. Two commonly used valves are gate valves and knife gate valves. Let’s explore their differences and understand when each type is most suitable. Gate Valves Construction: Gate valves consist of a body, bonnet, packing glands, stem, disk, wedge (or gates), handwheel, […]

Introduction Ceramic knife gate valves are essential components in various industries, designed to handle thick fluids, slurries, and wastewater. In this article, we’ll explore their working principles, types, advantages, and disadvantages. What Is a Ceramic Knife Gate Valve? A ceramic knife gate valve is specifically engineered for precise flow control. Its primary purpose […]

Signs Your Valve Needs Maintenance Valves play a crucial role in controlling the flow of fluids and gases in various industries. Regular maintenance is essential to ensure optimal performance and extend the lifespan of your valves. Here are some signs that indicate your valve might need maintenance: Internal Leaks Hunt down those sneaky leaks […]

Maintaining a knife gate valve involves several key steps to ensure its proper functioning and longevity. Here’s a general guide: Regular Inspection Check the valve for any signs of wear or damage, especially the sealing surfaces and the gate itself. Packing Adjustment Adjust the packing once a month to ensure a tight seal […]

Knife gate valves find applications in various industries due to their ability to handle challenging fluids and materials. Here are some common uses: Wastewater Treatment Knife gate valves are widely used in wastewater networks. They can handle thick, porous media with high concentrations of suspended solids, such as dense sewage sludge. These valves prevent leaks and ensure […]

Valves are essential components in piping systems, controlling the flow of fluids and gases. Two of the most common types of valves are gate valves and ball valves. Each type has its own unique advantages and disadvantages, making it important to understand their differences when selecting the best valve for a specific application. […]

What Are the Different Types of Forged Gate Valves? Forged gate valve is a common industrial valve widely used in pipeline systems to control the flow and pressure of fluids. Forged gate valves can be divided into many different types based on different designs and uses. This article will provide a comprehensive […]

What is a Forged Steel Gate Valve and How Does It Work? What is a Forged Steel Gate Valve? Forged steel gate valve is a valve used to regulate the flow of fluid in pipelines. It is made of forged steel, a strong and durable material that can withstand high pressure and temperature. […]

Valves are of utmost importance in the realm of industrial manufacturing as they have a vital role in governing the movement of fluids, gases, and various other substances. It is imperative to make a prudent choice when it comes to selecting the appropriate valve for your particular application since this decision directly impacts the efficiency […]

In the realm of industrial flow control systems, plug valves stand out as reliable and efficient gatekeepers, regulating the flow of various fluids and gases. To meet the diverse demands of numerous industries, a multitude of plug valve manufacturers have emerged, each leaving its mark on the global marketplace. Among these distinguished players, Lixin Valve […]

Valves are an essential part of any piping system, used to control the flow of fluids and gases. There are many different types of valves available, each with its unique advantages and disadvantages. In this blog post, we will explore the pros and cons of two common valve types: knife gate valves and plug valves. […]

In various industries, ball valves are widely used for controlling the flow of liquids, gases, and slurries. These valves provide reliable performance, ease of operation, and low maintenance requirements, making them a popular choice for a wide range of applications. With numerous manufacturers offering ball valves in the market, selecting the right supplier is crucial […]

Ball valves are one of the most common types of valves used in various industries, including oil and gas, chemical processing, and water treatment. They are known for their simple design, reliable performance, and ease of maintenance. With so many different brands of ball valves available, choosing the best one for your specific application can […]

Industrial Valve Manufacturer As an Industrial Valve Manufacturer, Lixin Valve Group is committed to providing high-quality and reliable valve solutions for various industries. Our expertise in valve engineering and manufacturing enables us to deliver valves that meet specific requirements and exceed industry standards. With our commitment to innovation, we strive to revolutionize the valve industry […]

In the field of industrial flow control, ceramic gate valves are the first choice for demanding applications that require exceptional resistance to corrosion, erosion, and abrasion. As a leading valve manufacturer, Lixin Valve Group has established itself as a trusted provider of high-quality ceramic gate valves for various industries, including oil and gas, chemical processing, […]

Knife gate valves are a type of industrial valve used to control the flow of fluids, typically liquids or slurries. They are characterized by a sharp, blade-like gate that slides across the flow path to open or close the valve. Knife gate valves are often used in applications where a tight seal is required, or […]

Rubber lined gate valves play a critical role in regulating the flow of various fluids in industrial and commercial applications. Known for their superior sealing capabilities, corrosion resistance, and durability, these valves have gained widespread acceptance across multiple industries. In this comprehensive blog post, we will delve into the world of rubber lined gate valves, […]

Valves hold immense significance in the realm of industrial and commercial applications. They assume a vital responsibility of overseeing the movement, force, and warmth of diverse liquids and gases. From governing the flow of water in public systems to managing the passage of chemicals in factories, valves stand as indispensable constituents that guarantee the smooth […]

In the realm of industrial operations, the selection of valves is crucial for ensuring efficient and reliable fluid control. Among the diverse range of valve types, ceramic knife gate valves have garnered increasing attention due to their remarkable properties and exceptional performance in demanding applications. This comprehensive guide delves into the benefits of utilizing ceramic […]

Maintaining and repairing a knife gate valve is essential to ensure its longevity and optimal performance. Lixin Valve Group, a leading manufacturer of knife gate valves, provides high-quality valves and offers valuable insights into their maintenance and repair procedures. Maintenance Regular maintenance can prevent problems and extend the life of your knife gate valve. […]

Knife gate valves are a type of industrial valve for flow control of liquids and gases. They are typically used in applications where a high level of flow control is required, such as in chemical processing, water treatment, and mining. Advantages of Knife Gate Valves 1.Tight shutoff: Knife gate valves provide a very tight […]

Knife gate valves are a type of industrial valve used to regulate the flow of fluids and materials. They are commonly used in applications where a tight shut-off is required, such as in the chemical, mining, and pulp and paper industries. Knife gate valves are also commonly used in water and wastewater treatment applications. […]

In the realm of industrial flow control, knife gate valves stand out as highly reliable and versatile components. Their unique design and construction make them ideal for a wide range of applications, spanning various industries. Be it the mining, wastewater treatment, or chemical processing industries, knife gate valves deliver unparalleled performance and durability. In this […]

Our metal seated Knife Gate Valve is made as per the specification of MSS SP-81.As we see, the article 10.2 of this standard specified the leakage rate of

It is necessary to verify that the upstream and downstream pipelines of the valve have been relieved of pressure before disassembling and disassembling

FAQ

What Valve Products Do You Offer?

How Is The Quality of Your Products?

We strictly test each product, using the most advanced testing equipment and strict scientific management. From design to production, we strictly follow the ISO production management system to ensure product quality meets factory standards.

How Is Your Customer Service?

We value customer satisfaction and provide professional pre-sales and after-sales services. If you have any questions or need support, please feel free to contact our customer service team.

What Is Your R&D Capability?

We have a strong R&D team dedicated to technological innovation and product improvement. We continuously introduce new products to meet the changing needs of our customers.

Do You Provide Customized Services?

Yes, we can customize products according to customers’ specific needs. If you have special requirements, you can contact our sales team for customized solutions.

Do You Have International Certifications?

Yes, our products have passed multiple international certifications, such as ISO 9001, CE, API 6D, etc.

Why Choose Lixin?

Excellent Quality Management

Lixin maintains rigorous quality management systems to ensure that each product meets international standards. With specialized testing equipment and an annual production capacity of 20,000 tons, their commitment to quality is unwavering.

Comprehensive Quality Assurance

Lixin rigorously tests every product, adhering to ISO production management systems to ensure that product quality consistently meets factory standards.

Advanced Global Fluid Control Solutions

Lixin focuses on designing and producing valves and related products, striving to provide cutting-edge fluid control solutions worldwide. Customization options are also available to create additional value for customers.

Robust Technical Support

With over 450 employees, including more than 50 senior and intermediate engineering technicians, Lixin boasts a strong technical team. Their 50,000-square-meter facility houses CNC machining centers, various large and medium-sized equipment, and specialized testing devices.

Diverse Product Line

Lixin manufactures a wide range of valves, including knife gate valves, plug valves, butterfly valves, ball valves, and ceramic valves.

Global Market Expansion

Lixin actively welcomes collaboration to create a brilliant future, aiming to expand the global valve market, promote the Lixin brand, and revitalize domestic industrial development.

Lixin Valve Group Co., Ltd. is a national-level non-regional group focusing on the research and development, production, sales and service of valves. Since its establishment in 2000, Lixin has continuously innovated technology and grown in scale. We are committed to providing customers with global advanced fluid control solutions and customizing products according to your needs to create more value for customers. If you need high-quality knife gate valves, Lixin Valve Group is your first choice!