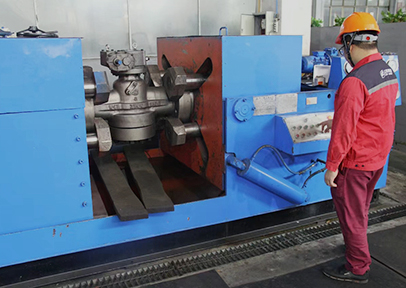

With a 3000mm large vertical lathe and other heavy horizontal lathes, we shape the material into the required workpiece for our industrial valves.

- About LIXIN

- ProductsGeneral ValveSpecial ValveKnife Gate ValveLugged Knife Gate ValvesFlange Knife Gate ValvesBonnet Knife Gate ValvesThrough Conduit Knife Gate ValvesLined Type Knife Gate ValvesKnife Gate Valve SeriesPlug ValveSleeve Plug ValvesLifting Plug ValvesDouble Block And Bleed Plug ValvesLubricated Plug ValvesEccentric Plug ValvesPlug Valve SeriesProduct Catalog Guide →

- Solution

- Blog

- Services

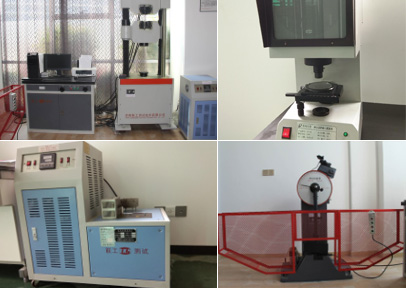

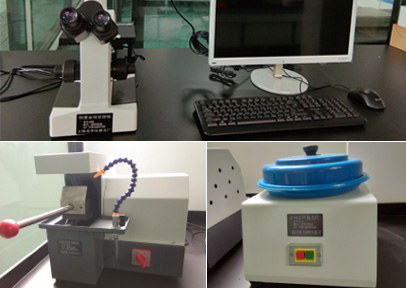

- Q Control

- Resoures

- Videos

- Contact