In the realm of industrial flow control systems, plug valves stand out as reliable and efficient gatekeepers, regulating the flow of various fluids and gases. To meet the diverse demands of numerous industries, a multitude of plug valve manufacturers have emerged, each leaving its mark on the global marketplace. Among these distinguished players, Lixin Valve Group shines as a leading force, consistently delivering exceptional products and services.

Navigating the World of Plug Valves: Understanding Their Significance

Before delving into the intricacies of the top plug valve manufacturers, it is essential to comprehend the significance of these valves in various industrial applications. Plug valves are quarter-turn valves, featuring a cylindrical or tapered plug that rotates within a cylindrical body to regulate flow. Their simple design and reliable performance make them ideal for numerous scenarios, including:

– Oil and Gas: Ensuring safe and efficient transportation of oil and gas through pipelines.

– Chemical Processing: Controlling the flow of corrosive and abrasive materials.

– Water Treatment: Regulating the passage of water in distribution and treatment systems.

– Mining and Power Generation: Facilitating the flow of heavy slurries and gases in harsh environments.

– Pharmaceutical and Food Processing: Maintaining sterility and hygiene in critical processes.

Unveiling the Top Plug Valve Manufacturers: A Journey into Excellence

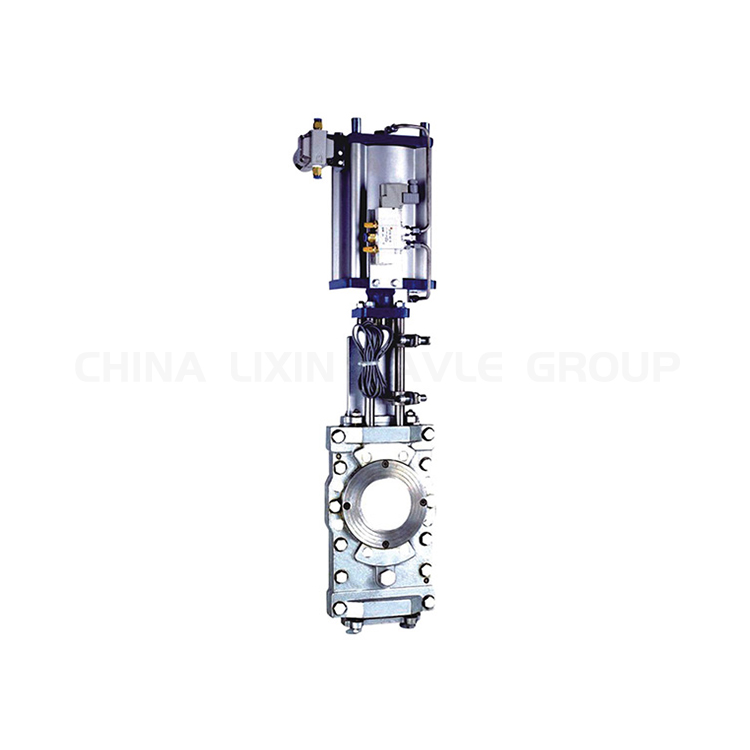

1. Lixin Valve Group: A Paragon of Innovation and Quality

Lixin Valve Group stands as a global leader in the manufacturing of high-performance plug valves. With a rich history spanning over three decades, the company has earned a reputation for excellence, continuously pushing the boundaries of valve engineering. Lixin’s dedication to innovation has resulted in a comprehensive portfolio of plug valves, encompassing a wide range of materials, sizes, and pressure ratings. The company’s unwavering commitment to quality ensures that its valves meet the most stringent industry standards, providing clients with reliable and long-lasting solutions.

2. Crane: A Legacy of Engineering Expertise

Crane is a revered name in the valve industry, tracing its roots back to the 19th century. With a rich history of innovation, Crane has consistently set benchmarks in valve design and manufacturing. Their plug valves are highly sought after for their exceptional durability and performance, making them a preferred choice for demanding applications in the oil and gas, chemical, and power generation sectors. Crane’s commitment to quality and customer satisfaction has solidified its position as a trusted partner for industries worldwide.

3. Flowserve: A Global Leader in Fluid Control

Flowserve stands as a global powerhouse in the fluid control industry, delivering comprehensive solutions for various applications. Their plug valves are known for their robust construction, ensuring reliable operation even under extreme conditions. Flowserve’s focus on research and development has resulted in innovative valve designs, optimizing flow efficiency and enhancing durability. Their comprehensive product range caters to a wide spectrum of industries, including oil and gas, chemical, mining, and water treatment.

4. Cameron: A Pioneer in High-Pressure Applications

Cameron is a leading provider of high-pressure plug valves, renowned for their exceptional performance in demanding environments. Their valves are meticulously engineered to withstand extreme pressures, making them ideal for applications such as deep-sea oil exploration and gas production. Cameron’s commitment to innovation has resulted in cutting-edge valve designs that maximize flow efficiency and minimize pressure drop. The company’s valves are highly sought after in industries where reliability and safety are paramount.

5. Velan: A Symbol of Durability and Versatility

Velan is a renowned manufacturer of plug valves, known for their exceptional durability and versatility. Their valves are meticulously designed and manufactured to withstand harsh conditions, ensuring reliable performance in demanding applications. Velan offers a diverse range of plug valves, catering to various industries, including oil and gas, chemical, mining, and power generation. The company’s focus on continuous improvement and customer-centric approach has solidified its position as a trusted partner for engineers and contractors worldwide.

A World of Reliable Flow Control Solutions

The plug valve manufacturing landscape is adorned with numerous exceptional players, each contributing to the advancement of flow control technology. From Lixin Valve Group‘s unwavering commitment to innovation to Crane’s legacy of engineering excellence, Flowserve’s global reach, Cameron’s expertise in high-pressure applications, and Velan’s dedication to durability and versatility, the industry is brimming with manufacturers dedicated to providing reliable and efficient solutions. As industries continue to evolve, these manufacturers will undoubtedly remain at the forefront, driving innovation and shaping the future of flow control systems.

Request a Quote

Request a Quote