Technical Specifications

| Size Range

NPS2″-16″/DN50-400mm |

Main Material

Cast iron |

| Temperature Rating

Soft Seat: -29 ~ +180°C |

Stem material

Stainless steel |

| Pressure Rating

I.0Mpa |

Directional /Stem Type

Bi-directional /Rising Stem |

| leakage level

Soft seat: / |

Body Style

Wafer |

| Disc Material

Stainless steel, Duplex steel etc. |

Flange Drilling

BS etc. |

| Seat Material

Soft Seat: NBR, EPDM |

Port Type

Full Port |

| Design Standard

MFR Standard |

Test Standard

MFR Standard |

| Face to Face

MFR Standard |

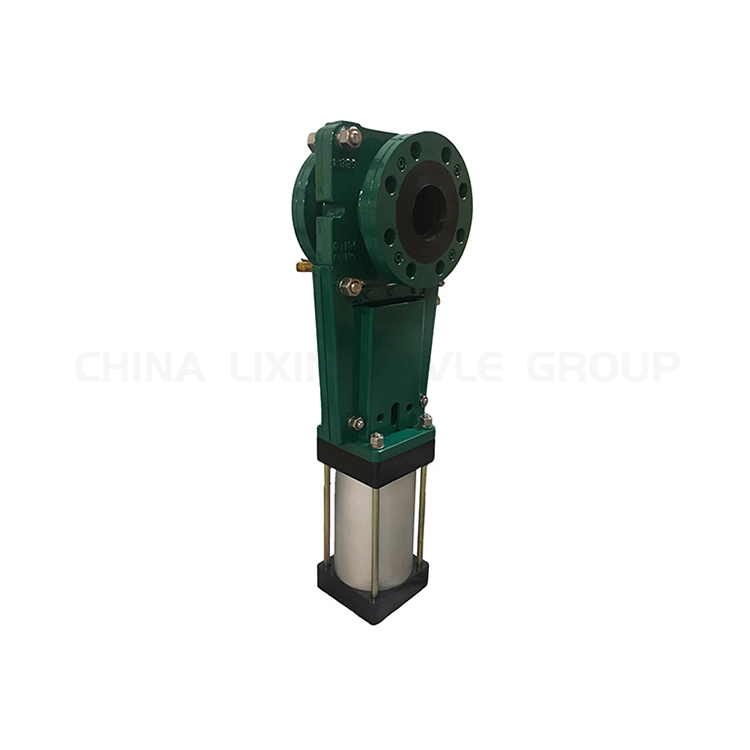

Operation

Handwheel, Worm Gear, Electric, Pneumatic etc |

| Application

Power, Mining, Pulp & Paper, Cement, Carbon Black, Chemical |

|

| Other

The carefully selected materials and contemporary design make our knife gate valve highly recognized. If our knife valve cannot meet your choice, we can provide you with special made. |

|

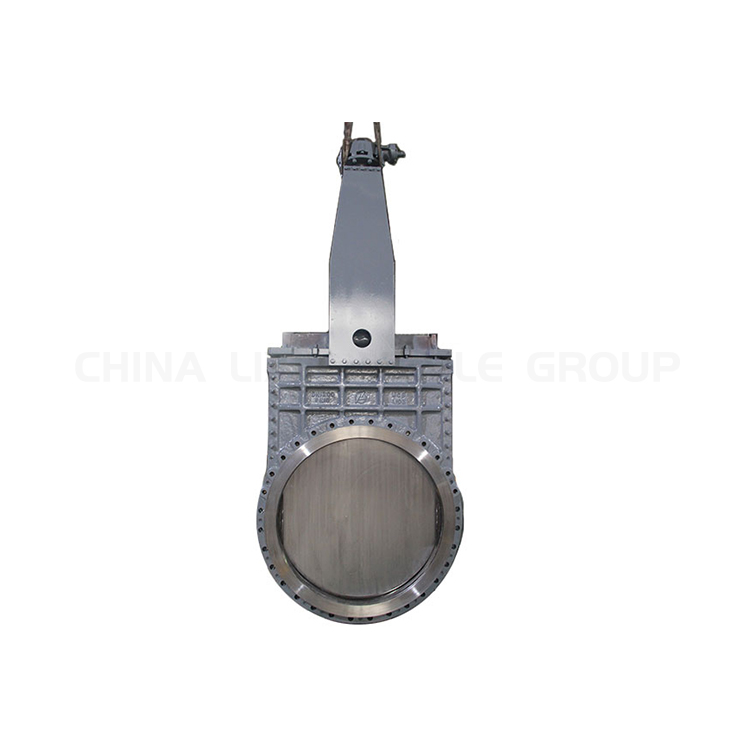

Chief Features

Channel without cavity,will not accumulate solids.

Channel and Flange RF surface is rubber lined,wearable.

Bi-directional seal.

No metal Parts in contact with the flowing media when the valve is in the full open position.

Field replaceable heavy duty elastomer sleeve.

The top bracket accept manual,pneumatic or electric for easy conversion.

Yoke design which consists of two plates that fully encloses the gate, spindle and Splatter that protects these components from slurry splatter that can harden and affect the operation of the valve.