Technical Specifications

| Size Range NPS2″-28″/DN50-700mm | Main Material Carbon steel, Stainless Steel, Aluminum Bronze, Duplex steel etc. (Other materials are available under request.) |

| Temperature Rating Soft Seat: -29 ~ +180°C Metal Seat: According to Main Material | Stem material Stainless steel |

| Pressure Rating I.0Mpa 1.6Mpa 150LB | Directional / Stem Type Bi-directional /Rising Stem |

| leakage level Soft seat: Zero Leakage Metal Seat: | Body Style Wafer |

| Disc Material Stainless steel, Duplex steel etc. | Flange Drilling ASME B16.5, EN1092, etc. |

| Seat Material Soft Seat: NBR, EPDM, PTFE, Viton etc. Metal Seat: Same to Body, STL etc. | Port Type Full Port |

| Design Standard MFR Standard | Test Standard MFR Standard |

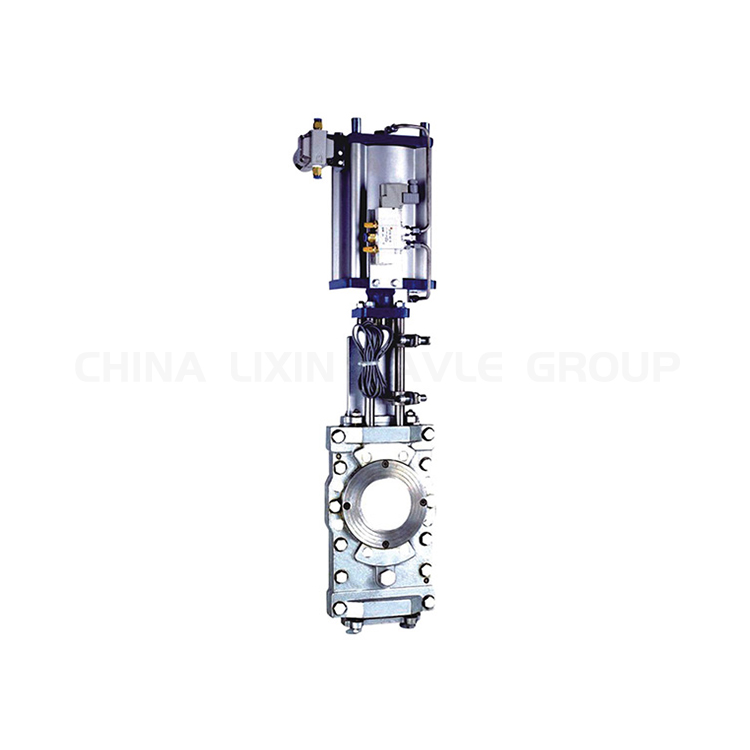

| Face to Face MFR Standard | Operation Handwheel, Worm Gear, Electric, Pneumatic, etc. |

| Application Mining, Pulp & Paper, Cement, Carbon Black, Chemical, Wastewater |

| Other The carefully selected materials and contemporary design make our knife gate valve highly recognized. If our knife valve cannot meet your choice, we can provide you with special made. |

Chief Features

Face to face dimensions adopt short series, and light weight valve is adopted, so as to save pipe supporter.

When the valve is open, the flow port has no groove and the medium will not be blocked.

The lifting disc is always consistent with the sealing surface whether it is fully open and closed. The sealing surface is not exposed and the channel is protected from direct scouring by the medium, thus extending the service life.

The sealing seat is designed with movable structure, which is easy to replace.

The bi-directional seat with movable sealing ring, and the direction is not be limited.

There are flushing holes on both sides of the valve for cleaning the inner cavity of the valve.