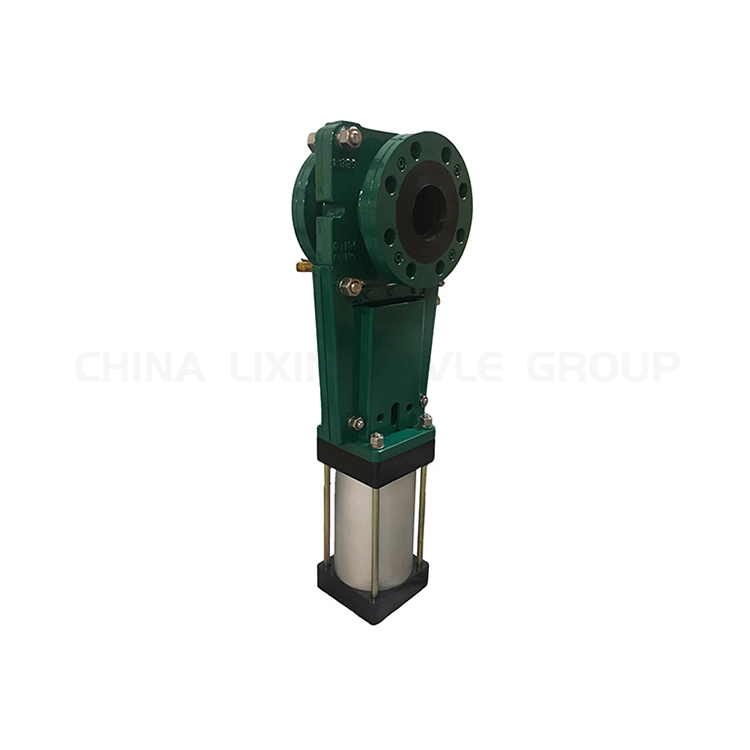

Step 1: Determine Fluid Characteristics Identify the type of fluid being handled (e.g., water, oil, gas, chemicals). Consider fluid properties such as temperature, pressure, viscosity, and corrosiveness. Step 2: Specify Pressure and Temperature Requirements Determine the maximum pressure and temperature that the valve will experience. Select a valve with a pressure rating and temperature range that meet or exceed these requirements. Step 3: Calculate Flow Rate Determine the desired flow rate through the valve. Calculate the valve size based on the flow rate and pipe diameter using flow equations or manufacturer‘s guidelines. Step 4: Choose Valve Type Standard Butterfly Valves: Suitable for general applications with moderate pressure and temperature requirements. High–Performance Butterfly Valves: Engineered for demanding applications requiring tight shut–off, low torque, and extended service life. Triple Offset Butterfly Valves: Ideal for high–pressure and temperature applications due to their triple offset design, which ensures complete sealing. Step 5: Select Body and Seat Materials Choose materials that are compatible with the fluid being handled and can withstand the operating conditions. Common materials include cast iron, ductile iron, stainless steel, and exotic alloys. Step 6: Determine Actuator Type Manual Actuators: Suitable for infrequent operation or applications where precise control is not required. Electric Actuators: Provide remote operation and precise control, ideal for automated systems. Pneumatic Actuators: Offer fast response times and high torque, suitable for high–pressure applications. Step 7: Consider Additional Features Lugs or Flanges: Select valves with lugs for direct mounting to flanges or piping systems, or flanges for secure and leak–proof connections. Sealing Options: Specify resilient seats for general applications or metal seats for high–temperature and corrosive environments. Step 8: Verify Compliance and Certifications Ensure that the valve meets industry standards and certifications (e.g., ANSI, API, ISO). Consider valves with third–party approvals for specific applications (e.g., fire safety, nuclear). Conclusion By following these steps and considering the factors discussed above, engineers and professionals can select the right butterfly valve for their specific application. Proper valve selection ensures optimal flow control, system efficiency, and long–term reliability. External Resources How to Size a Butterfly Valve Additional Information Table: Butterfly Valve Selection Criteria Criteria Considerations Fluid Characteristics Type, temperature, pressure, viscosity, corrosiveness Pressure and Temperature Requirements Maximum pressure and temperature ratings Flow Rate Desired flow rate and pipe diameter Valve Type Standard, high–performance, triple offset Body and Seat Materials […]