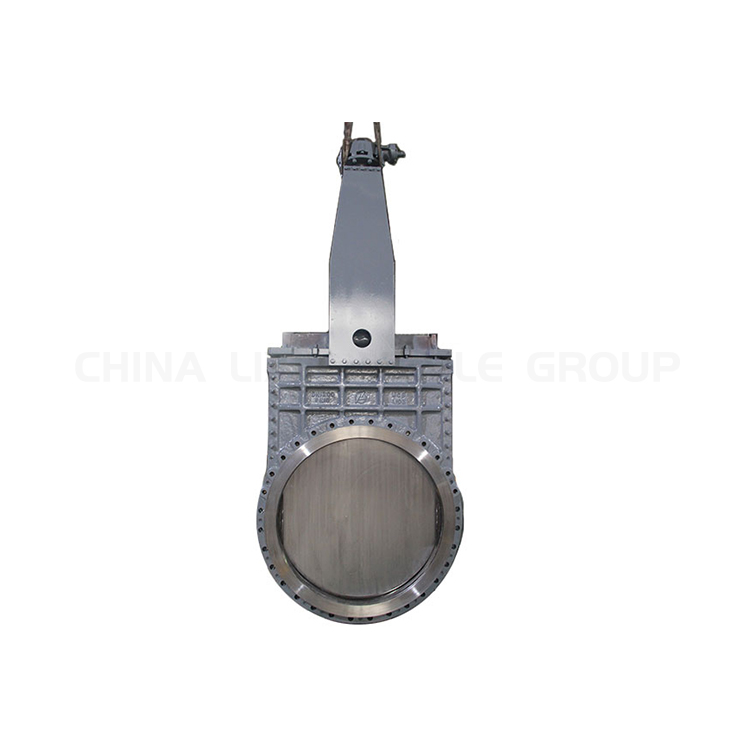

Introduction Butterfly valves are quarter–turn valves that regulate fluid flow by rotating a disc–shaped closure element (butterfly) within a cylindrical body. They offer several advantages, including compact design, low maintenance, and bidirectional flow capability. This comprehensive guide provides a detailed overview of butterfly valves, including their design, types, selection criteria, and applications, with a focus on high–performance, triple–offset, lugged, and flanged butterfly valves. Design and Construction Butterfly valves consist of a cast or forged body, a resilient seat, a butterfly disc, and an actuator. The body is a cylindrical housing containing the valve components. The resilient seat forms a seal against the disc, preventing fluid leakage. The butterfly disc is a rotating plate that controls the flow of fluid. The actuator, either manual or automated, opens and closes the valve by rotating the disc. Types of Butterfly Valves Butterfly valves are available in various types based on their design and application: High–Performance Butterfly Valves: Engineered for demanding applications, offering tight shut–off, low torque, and extended service life. They feature precision–machined components and advanced sealing technologies. Triple Offset Butterfly Valves: The disc is offset in three directions (eccentric, parallel, and conical), ensuring complete sealing even under high–pressure and temperature conditions. Lugged Butterfly Valves: Designed with lugs on the body for direct mounting to flanges or piping systems. They offer easy installation and maintenance. Flange Butterfly Valves: Constructed with flanges on the body for bolting between pipe flanges. They provide a secure and leak–proof connection. Selection Criteria Selecting the appropriate butterfly valve for an application involves considering several factors: Fluid Type: Corrosive, abrasive, or viscous fluids may require specific material compatibility. Temperature: Valve materials must withstand the operating temperature range of the fluid. Pressure Rating: The valve‘s pressure rating must meet or exceed the system‘s maximum pressure. Flow Rate: The valve‘s flow capacity should accommodate the desired flow rate. Valve Size: The valve size is determined based on the pipe diameter and flow requirements. Materials of Construction: Valve components should be corrosion–resistant and durable for the intended application. Actuator Type: Manual, electric, or pneumatic actuators are available depending on the desired level of automation and control. Applications Butterfly valves find widespread use in various industries, including: Water and Wastewater Treatment: Regulating flow in pipelines, distribution systems, and treatment plants. Petroleum and Gas: Controlling flow in pipelines, refineries, and exploration facilities. Chemical Processing: Handling corrosive or abrasive fluids in chemical plants. HVAC Systems: Regulating airflow in heating, ventilation, and air conditioning systems. Food and Beverage Industry: Controlling fluid flow in sanitary environments. Advantages and Disadvantages Advantages Compact design and low weight Easy to install and maintain Bidirectional flow capability Reduced pressure drop Wide range of sizes and materials Disadvantages Limited pressure rating compared to other valve types Potential for leakage at high pressures Not suitable for throttling applications Conclusion Butterfly valves offer a versatile and cost–effective solution for regulating fluid flow in various applications. By understanding their design, types, selection criteria, and applications, engineers and professionals can optimize valve performance and system efficiency. External Resources […]