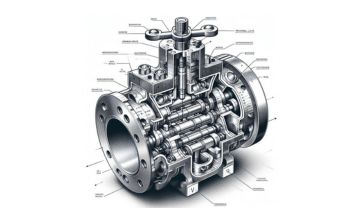

In the realm of industrial fluid control, ball valves and butterfly valves stand as two prevalent choices for isolating, regulating, or directing the flow of liquids and gases. While they share some fundamental similarities, these valves exhibit distinct characteristics that influence their suitability for different applications. This comprehensive blog post will delve into the intricacies of ball valves and butterfly valves, comparing their design, functionality, advantages, and limitations. By the end of this exploration, you will gain a profound understanding of these critical components and how to make informed decisions when selecting the appropriate valve for your specific requirements. Design and Functionality Ball ValveA ball valve, as the name suggests, utilizes a spherical ball as its closure element. The ball is perforated with a bore that aligns with the direction of flow when the valve is open. When closed, the ball rotates 90 degrees, blocking the flow path. Ball valves provide a robust seal and can handle high pressures and temperatures. Butterfly ValveIn contrast, a butterfly valve employs a circular disc as its closure mechanism. The disc is mounted on a shaft that traverses the center of the valve and rotates 90 degrees to open or close the valve. Butterfly valves excel in applications where rapid flow modulation or frequent on–off cycling is required. Advantages and Disadvantages Ball Valve Pros: Bi–directional sealing: Ball valves can seal in both directions, offering versatility in flow control. High–pressure and temperature capabilities: Robust construction enables ball valves to withstand extreme conditions. Low maintenance: The simple design minimizes the need for frequent maintenance interventions. Cons: Higher initial cost: Ball valves tend to be more expensive than butterfly valves of comparable size. Limited flow capacity: The spherical closure element can restrict flow rate compared to butterfly valves. Butterfly Valve Pros: Lower cost: Butterfly valves are generally more economical than ball valves. Higher flow capacity: The circular disc design allows for a larger flow area, resulting in higher flow rates. Rapid actuation: The 90–degree rotation of the disc facilitates quick operation. Cons: Lower pressure rating: Butterfly valves are typically limited to lower pressure applications. Unidirectional sealing: Butterfly valves seal effectively in one flow direction only. Applications The choice between a ball valve and a butterfly valve hinges on specific application requirements. Here are some common applications for each type: Ball Valve High–pressure pipelines Process industries requiring bi–directional flow control Isolation and shut–off applications Butterfly Valve Moderate–pressure pipelines HVAC systems Rapid flow modulation or frequent on–off cycling Comparative Table For a concise overview of the key differences between ball valves and butterfly valves, refer to the following table: Feature […]